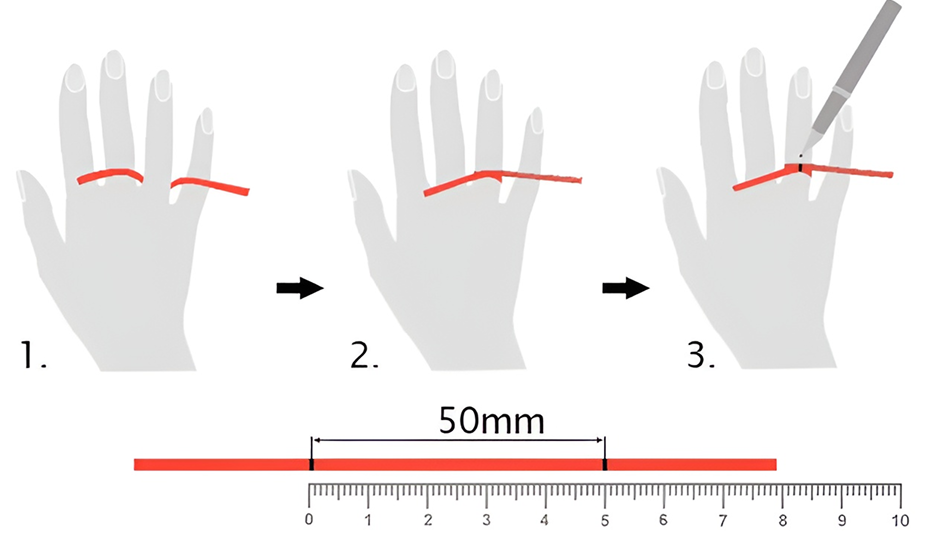

know the size

- 1. Select an existing ring that fits the desired finger.

- 2. Measure the internal diameter of the ring in mm.

- 3. Select the diameter below to determine your ring size.

The first step in developing excellent quality, strong porcelain is the careful selection of raw materials. Porcelain is made up of kaolin, feldspar, and quartz which each have an important role:

The raw materials will be extracted and transported to the manufacturing facility for preparation. In the preparation process, the raw materials will be crushed, ground into powder, mixed with water to produce a slurry and filtered to remove contaminents. Once the mixture is complete, it is processed to achieve uniform particle size and consistent density, which is key for producing premium quality porcelain.

The forming stage is when the prepared porcelain materials are shaped into usable or commercial forms. High quality clay (mostly kaolin, but also containing feldspar and quartz) is mixed with water to create a plastic material called porcelain slip.

The slip can then be formed using a variety of forming methods. The most common method is called slip casting, where the slip is poured into a porous plaster mold. The plaster absorbs the water from the slip, causing the layer of clay to solidify on the inner walls of the mold. Once the desired thickness is achieved, the excess slip is removed from the mold, leaving behind a hollow, well-defined-shaped object.

Slip casting is extremely popular because it is highly versatile, while allowing for complex and detailed forms with extremely limited manual labor. Slip casting is one of the most time-efficient forming processes in porcelain manufacture.

Drying is an important phase in production of porcelain, as it preps clay body for firing in the kiln. During the drying stage, moisture is removed slowly, and the porcelain has enough strength and stability to endure subsequent firing.

Newly molded porcelain has considerable amount of water, and is very soft and structurally weak. The drying process must be deliberate and slow to minimize cracking, warping or other undesirable outcome. Moisture is sequentially diminished, so that the piece maintains its shape.

Drying can occur naturally through air drying, or in drying rooms with controlled heating and humidity parameters. In controlled drying rooms, factors such as airflow, temperature, and humidity are optimized and controlled so the drying occurs evenly and consistently. This step is essential for producing a high-quality porcelain, and reducing defects such and cracking, warping, and other discolorations.

Firing is an important process in porcelain production, where the shaped wet clay now goes through a firing process, converting the shaped clay into a strong ceramic, glass-like material. This is generally done in a kiln, at high temperatures, usually between 1,200 and 1,400 °C (2,192 and 2,552 °F). At these temperatures, vitrification occurs- the clay particles fuse together to create a non-porous, dense and often translucent material.

Generally speaking, the firing process starts off with a bisque firing, a first firing of the vessel at a lower temperature. This bisque firing removes all the remaining moisture (if any) and organic materials from the porcelain body. In this first firing, the vessel becomes stronger and durable enough to be safely handled before glazing.

After bisque-firing, the delicate porcelain is completely covered with a final liquid glass covering - their glaze. The glaze goes through a firing process, just like your greenware, which transforms it into a durable scenario that also provides a water-resistant gloss surface. It adds beauty to porcelain and is the final development stage in which porcelain is changed visually and chemically from the bisque-firing to glazing process.

Glazing also enhances color, patterns, and surface effects to give a refined and polished look. Glazes can be produced for (almost) every color and shade imaginable and are great for applying textures or fine patterns. You can even duplicate looks of some natural stone, wood or fabric. This versatility makes glazed portfolio appropriate for residential and commercial application.

Quality control in porcelain manufacturing is a thorough process characterized by multiple phases. The process begins with the selection of minerals—the appropriate minerals are high-purity kaolin, feldspar, and quartz. The use of true minerals in a single phase establishes that the materials used will not have impurities caused by human factors that could impair end product integrity.

Once the minerals are selected, each one is extensively and carefully tested and characterized in the laboratory. Each mineral is tested chemically for purity, analyzed for particle size distribution, and examined for plasticity, using strict guidelines. Each evaluation insures that the minerals selected meet the specifications for producing porcelain on strength, uniformity, and appearance quality.

4 products

Empty cart

$130.00

$150.00

$130.00

Add gift wrap

Order note

Shipping

SUGGESTION FOR YOU